Pre-ProcessingIndustrial WasteMaterial

Smart Waste Disposal for a Cleaner Future

Our Pre-Processing Services

Comprehensive industrial waste pre-processing solutions for optimal recycling and disposal

Collection

Our hazardous waste collection program ensures that waste is handled safely from the moment it leaves your facility.

Transportation

We operate a fully licensed fleet equipped to transport hazardous waste in accordance with all safety and environmental guidelines

Pre-Processing Solutions

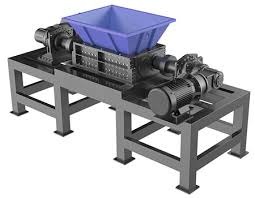

Industrial waste can be used in energy recovery or industrial processes; it often requires treatment or conditioning. Our preprocessing services optimize waste materials for safe and efficient use.

Waste Collection & Transportation, Initial Characterization and Sorting, Size Reduction (Shredding/Grinding), Mixing & Blending, Quality testing to meet co-processing in Cement Kilns.

We convert hazardous waste into consistent, manageable, and compliant material ready for energy recovery or further treatment.

Cement Co-Processing

Co-processing is an environmentally responsible method of recovering energy and raw materials from waste through industrial processes—most commonly in cement kilns.

- Zero waste sent to landfills

- Reduced fossil fuel consumption

- Lower carbon footprint for industries

- Full thermal destruction of hazardous compounds

We supply pre-processed waste materials as alternative fuels and raw materials (AFR) to partner facilities, ensuring maximum energy efficiency and minimal environmental impact.